In the dynamic world of packaging, cast film plays a pivotal role in ensuring products are efficiently and safely wrapped. This type of film is produced through the casting process, a particular method that results in a film known for its clarity and versatility. Understanding the intricacies of cast film can greatly benefit businesses looking for optimal packaging solutions, from food packaging films to more specialized needs such as stretch film. This article will explore the manufacturing processes, inherent characteristics, and the diverse applications where cast films are indispensable, alongside providing insight into its advantages and limitations.

Manufacturing Process

The manufacturing of cast film involves a systematic approach where the film is extruded through a flat die and then rapidly cooled to produce a smooth and crystal-clear surface. The process begins with melting resin pellets, which are then forced through the die, forming a thin sheet. This sheet is immediately cooled using chilled rollers, a technique that differentiates cast films from other types like blown films.

Here is a simplified table outlining the steps in the cast film manufacturing process:

Stage | Description |

Melting | Resin pellets are heated until molten. |

Extrusion | The molten resin is extruded through a flat die. |

Cooling | Film is cooled on chilled rollers. |

Winding | Cooled film is cut to size and wound onto rolls. |

This efficient process allows thermoforming packaging to produce high volumes of film efficiently, making it cost-effective and widely used in industries such as food packaging and logistics.

Key Characteristics

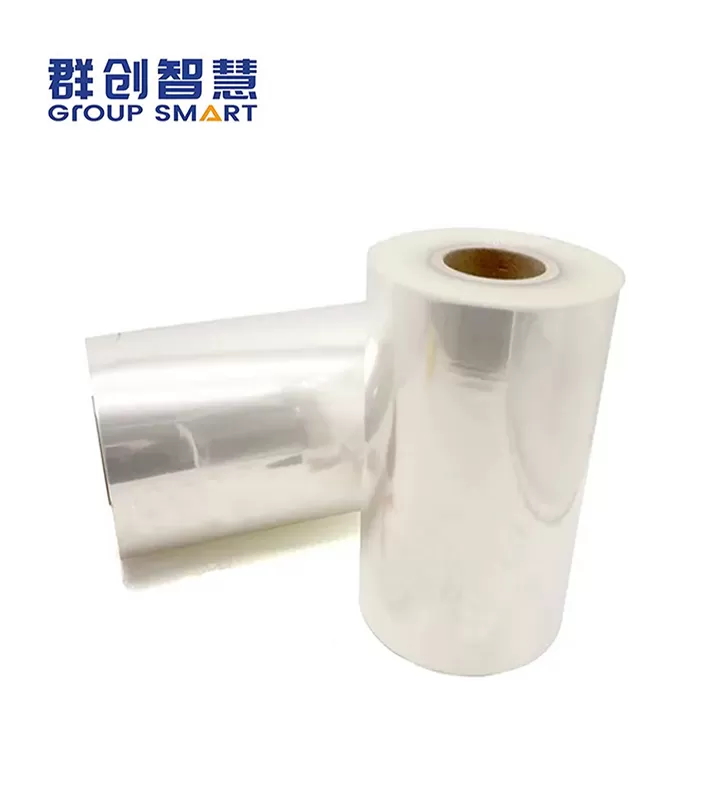

Cast films are known for several distinct characteristics. Primary among these is their high transparency, which is crucial for applications requiring good visual appearance, such as lidding film food packaging. Furthermore, cast films offer excellent tear resistance and stretch capability, making them ideal for use as stretch films suppliers.

Some of the key characteristics of cast films include:

Characteristic | Benefit |

Transparency | Enhances aesthetic appeal and presents product clarity. |

Gloss | Provides a shiny finish adding a premium feel to packaging. |

Consistency | Uniform thickness ensures reliability in application. |

Strength | Improves handling and reduces puncture risk. |

These characteristics make cast films particularly valuable for applications demanding robustness and integrity, such as vacuum packaging bags for food.

Applications

Cast film finds use in a variety of applications due to its unique properties. In the food industry, it is commonly used as lidding film and packaging films that require a high barrier against moisture and contaminants.

Various applications of cast film include:

Application | Description |

Food Packaging | Ensures product freshness and shelf appeal. |

MDO Stretch Wrap | Laminated printing with other materials for reduced film demand and cost savings. |

Barrier Films | Protects against oxygen and moisture for perishable goods. |

Medical Packaging | Provides sterile barrier for sensitive items. |

The adaptability of cast film makes it a critical component for industries looking to enhance the longevity and presentation of their products, offering a resilient packaging solution that fulfills diverse needs.

Advantages

There are several advantages to using cast films. One of the main benefits is its cost-effectiveness due to the high production speed and low maintenance requirements of the manufacturing process. Additionally, MAP packaging often relies on cast films for their ease of use and fast unwind, which contribute to improving operational efficiency.

Advantages include:

Advantage | Impact |

High Production Rate | Reduces costs and increases production throughput. |

Uniform Thickness | Ensures safety and performance reliability. |

Excellent Clarity | Improves the appearance of packaged goods. |

Easy Unwind | Simplifies application and enhances productivity. |

These advantages make cast films an attractive choice for companies seeking efficient packaging solutions that can keep pace with their operational demands.

In conclusion, cast film serves as a vital material within the packaging industry, offering significant benefits in clarity, cost-effectiveness, and application versatility. Whether it is used for vacuum pack rolls or vacuum pack freezer bags, its ease of production and distinctive qualities continue to make cast films a preferred solution for numerous packaging needs. By understanding both its advantages and limitations, businesses can more effectively leverage cast films to enhance their packaging processes, ensuring both product protection and aesthetic appeal in a competitive market.