| Product | Structure | Characteristics | Usage scenario |

| GS-MDO AAE | MDO PA/PE | | Suitable for freezing and short-term cold storage Multilayer co-extrusion casting process with excellent flatness Can be printed and laminated with other films

|

|

|

| GS-MDO AEE-T | MDO PA/PE

(Super transparent) | Low haze, ultra-transparent Deep-freeze durable & puncture-resistant Thickness range 50–180 microns

| |

|

|

| GS-MDO AHE | MDO PA/EVOH/PE | | |

|

|

| GS-MDO AAP | MDO PA/PP | | |

|

|

| GS-MDO APP-T | MDO PA/PP

(Super transparent) | Medium-barrier&ultra-transparent Excellent tensile strength and abrasion resistance Suitable for 121°C retort sterilization

| |

|

|

| GS-MDO AHP | MDO PA/EVOH/PP | Heat-resistant EVOH with ultra-high barrier properties Excellent tensile strength and abrasion resistance Suitable for 121°C retort sterilization

| |

|

|

| GS-MDO EOE | MDO PE/EVOH/PE | EOVH layer for high barrier & flavor preservation High mechanical strength, Puncture-resistant Deep-freeze durable for extended frozen storage

| |

|

|

More about Cast MDO Stretch Film

Custom Stretch Film

Our MDO cast stretch film is fully customizable to meet different packaging needs. Whether you require specific film thicknesses, tailored roll widths, or particular mechanical properties, we can deliver a solution built for you. With longitudinal orientation and precision co-extrusion, this stretch film offers exceptional puncture resistance and tensile strength while minimizing film usage, giving you cost savings and efficient load stability.

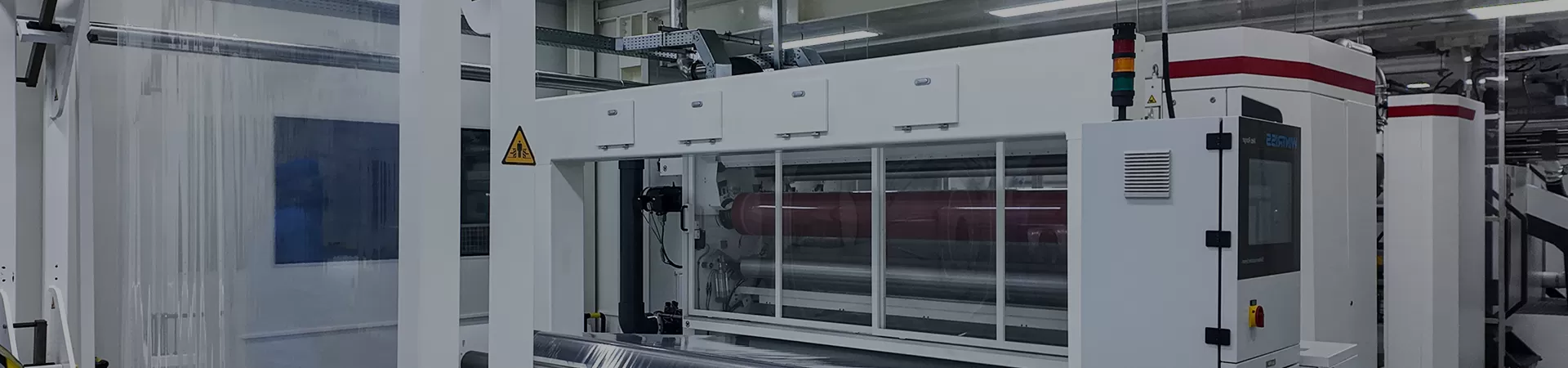

Stretch Film Material

Constructed via advanced multilayer co-extrusion cast film technology, our cast stretch film leverages oriented polymer chains in the machine direction to deliver enhanced mechanical performance and processing efficiency.

By selecting material combinations like PA/PE film, PA/EVOH/PE film or other high-barrier structures you benefit from excellent load retention, superior flatness and compatibility with automatic stretch wrapping equipment.

Stretch Film Uses

High-demand packaging: Thanks to its multilayer cast structure, it serves markets requiring enhanced barrier and mechanical protection, such as food, pharma, electronics or logistics.

Efficiency-driven operations: With its oriented film design, you can reduce material usage and improve line speed and throughput, giving you both cost and sustainability advantages.