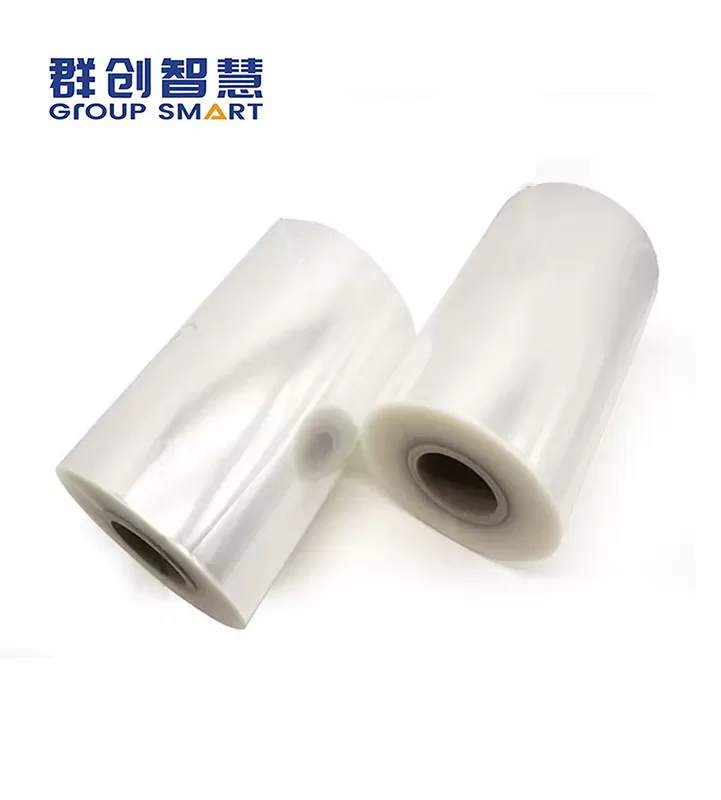

GroupSmart is a trusted supplier of high-quality cast films and coextruded films, catering to manufacturers and exporters worldwide. Our films are engineered for exceptional clarity, strength, and versatility, making them ideal for packaging, laminating, and industrial applications. With advanced production technology and strict quality control, we ensure consistent performance, durability, and customization to meet diverse industry needs. Whether for food packaging, pharmaceutical sealing, or specialty uses, GroupSmart delivers reliable solutions with competitive pricing and global shipping. Partner with us for innovative film products that enhance efficiency and product protection. Discover how our cast films can elevate your business—contact us today for tailored wholesale options.

Advantages of GroupSmart Cast Films

Cast film process with tight thickness tolerance and superior flatness. This film functions both as an independent barrier packaging material and as a printable substrate for lamination

Exceptional mechanical properties and ultra-strong heat-sealing performance, ensuring safety for food, medical, and other packaging applications

11-layer co extrusion in packaging casting technology with advanced manufacturing processes, enabling diversified coextrusion film product structures and customized solution